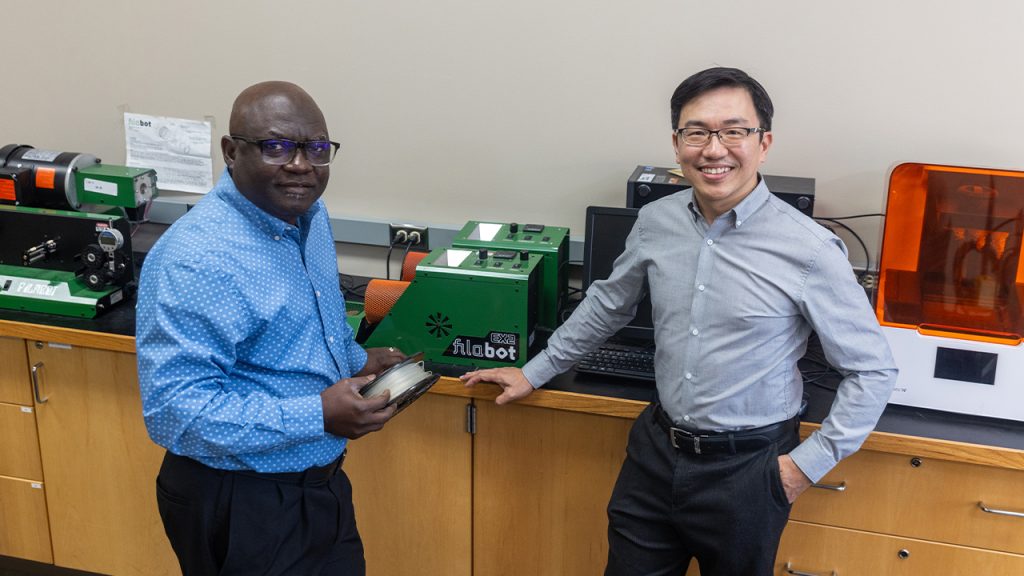

Dr. John Obielodan (left) and Dr. Joseph Wu (right) in the lab following the announcement of their U.S. patent. “It is a tremendous accomplishment to receive a U.S. patent as it is a rigorous process that recognizes the novelty of this invention,” said President Arjun Sanga, WiSys.

By Christine Bellport, public relations specialist, UW–Platteville. Original article can be found here

With support from Wisconsin’s Dairy Innovation Hub, a groundbreaking patent will give dairy waste a second life in 3D printing

In a powerful blend of agricultural ingenuity and sustainable technology, two University of Wisconsin-Platteville professors have patented a revolutionary way to turn spoiled milk into biodegradable plastic—paving the way for new markets for dairy producers and a greener future for manufacturing.

The project, backed by early and ongoing support from the Dairy Innovation Hub, showcases what’s possible when innovation meets investment. Using milk proteins like casein and whey, the team developed a 3D printing material that replaces petroleum-based plastics with a renewable, eco-friendly alternative.

“Who would have thought 3D printing and dairy protein could be combined to create a new material?” quipped Dr. Joseph Wu, associate professor of chemistry. “My hope is that it will help both dairy farmers in Wisconsin and the 3D printing industry.”

From spoiled milk to sustainable innovation

The research was sparked during the COVID-19 pandemic, when milk dumping brought attention to the industry’s vulnerabilities. Professors Wu and Dr. John Obielodan, chair of mechanical and industrial engineering, began exploring how discarded dairy proteins could be repurposed as high-performance polymers.

The answer? A patented process to convert casein and whey into durable, flexible materials suitable for 3D printing and beyond.

“We knew dairy products contain proteins like casein and whey,” observed Obielodan, professor and chair of the Department of Mechanical and Industrial Engineering. “We asked ourselves, ‘Why can’t this milk, instead of being wasted, be turned into something valuable?’”

That simple question ignited a five-year journey of experimentation, development and persistence. The effort culminated in WiSys being awarded a U.S. patent for a novel method of transforming dairy waste into usable plastic—a breakthrough with global significance as the widespread use of non-biodegradable, petroleum-based plastics remains a major concern.

The Dairy Innovation Hub’s role

The research was made possible by a two-year, $50,000 grant from the Dairy Innovation Hub, a state-supported initiative linking UW-Platteville, UW-Madison and UW-River Falls. Over time, additional funding brought the Hub’s total investment in the project to approximately $180,000.

“As farmers and innovators, we believe in the quality and power of milk,” said Maria Woldt, program manager for the Dairy Innovation Hub. “It’s really inspiring to see researchers like Dr. Wu and Dr. Obielodan finding alternative uses for this safe, high-quality, natural and sustainable product.”

The project was among the very first funded by the Dairy Innovation Hub, and its success reflects the Hub’s mission to drive innovation in research, teaching and outreach for the state’s $52.8 billion dairy industry.

A circular economy for dairy

Beyond its immediate scientific and agricultural benefits, the invention contributes to the growing circular economy movement—turning food waste into valuable new products while reducing the environmental burden of traditional plastics.

“Farmers work to avoid waste, and the motivation behind this project aligns with that core value,” added Woldt. “We are thrilled that after a little more than five years we helped move an innovative idea forward that will lead to additional uses for milk. Tangible examples like this show we are delivering on that promise.”

Looking ahead, the patent opens the door for commercialization, and future products could range from 3D printer filaments to biodegradable containers, custom tools, and even medical devices, all derived from dairy.

“This is what happens when universities, researchers and agriculture invest in innovation together,” Wu said. “We’re connecting the dots between sustainability and industry—and it all started with a glass of milk.”

For more additional information, visit: Spoiled Dairy into 3D Sustainable Plastic.

About the Dairy Innovation Hub:

The Dairy Innovation Hub, which the state of Wisconsin is supporting to the tune of $7.8 million per year, harnesses research and development at UW-Platteville, UW-Madison and UW-River Falls campuses to keep Wisconsin’s $52.8 billion dairy community at the global forefront in producing nutritious dairy products in an economically, environmentally and socially sustainable manner.